Single particle inductively coupled plasma mass spectrometry (spICP-MS) (ISO 2017b) is emerging as a robust method for the measurement of nanoparticle concentration but can only be applied to nanoparticles which contain elements detectable in ICP-MS. Condensation particle counters (CPCs) (CEN 2015) can measure the concentration of particles within a broad size range but require these to be aerosolised. 2016) also makes use of diluted samples can detect particles with diameters larger than 50 nm and requires the dispersion of the samples in electrolytes. Tunable resistive pulse sensing (TRPS) (Vaclavek et al. The minimum detectable particle size depends on the material and is typically around 10 nm for gold, 40 nm for silica and even higher for liposomes. Particle tracking analysis (PTA) (ISO 2016) can be used with a wide variety of materials but requires very dilute samples, which imposes some constraints on the preparation of stable samples. Small-angle X-ray scattering (SAXS) (ISO 2015), on the contrary, can be used to measure the concentration of a range of different materials, but the measurement of particles that are not spherical, has unknown density or whose size is larger than 100 nm is challenging. 2018b) but its application to other materials is limited by the lack of knowledge of the optical properties of the materials. For example, UV-visible spectroscopy (UV-Vis) is widely used to measure the concentration of gold nanoparticles (Haiss et al.

The choice of the instrument often depends on the materials and the size range of the particle samples. The measurement of nanoparticle concentration also enables compliance with present and future regulation, linked, for example, to the EC Recommendation for the definition of a nanomaterial (2011/696/EU) (European Commission 2011).Ī number of instruments are currently available to the community for the measurement of nanoparticle concentration.

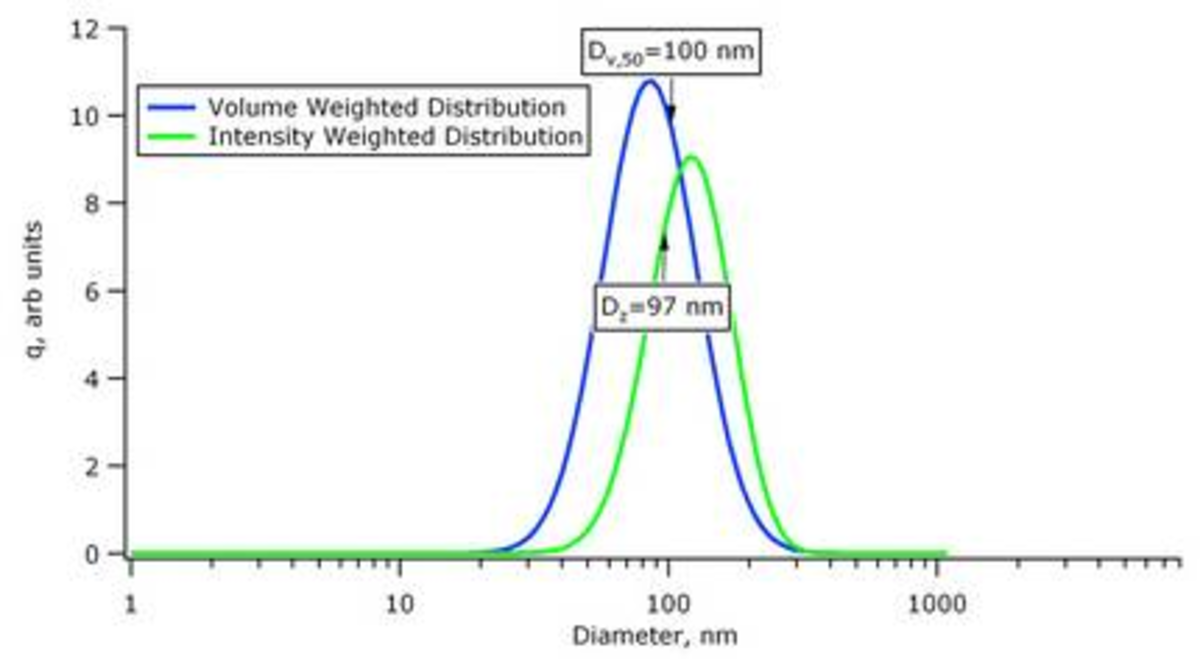

The risk of exposure to nanomaterials is related to their concentration, and similarly, the dose of a nanoparticle-based medicine depends on the concentration of the nanoparticles in solution, as well as their loading with active ingredients. For example, the direct measurement of nanoparticle concentration, along with other properties of the materials, is a means to test product stability, lifetime and variability across different batches or production sites. Measuring the number concentration of colloidal nanoparticles is of critical importance to industries producing and using high-value nanoparticle materials, as this enables the implementation of effective quality assurance (QA) and quality control (QC) protocols, formulation of related risk assessments and compliance to regulation. 2011), energy (O'Regan and Grätzel, 1991), catalysis (Corma and Garcia 2008), electronic (Talapin and Steckel 2013) and cosmetic (Indu and Rumjhum 2007 Monteiro-Riviere et al. 2015), including medical (Balasundaram and Webster 2006 Boccaccini et al. High-added value nanoparticles are used in a range of industrial sectors (Stark et al. These features make it an ideal tool to support both development and quality control of particle materials for a broad range of applications. Overall, we show that MADLS® is a rapid and straightforward method for the reproducible measurement of particle concentration, as well as size, requiring minimal sample preparation, without the need to calibrate using a pre-determined concentration series, and applicable to a broad range of materials. A linearity of within 40% across a concentration range of 3♱0 8 to 2♱0 11 mL −1 for concentration measurements was also demonstrated by using gold nanoparticles and gravimetric dilutions for method validation. The repeatability of the measurements, in terms of relative standard deviation, is typically below 30%. Here it is shown that the level of accuracy that can be expected for the concentration of particles is typically within 50% of the nominal value across a range of materials and sizes and, for some samples, within 20%. We show that the concentration working range depends on the material’s optical properties, size and concentration. We evaluate the method accuracy, linearity and reproducibility, as well as the operational nanoparticle concentration and size range. We describe the theory of the method and its application to nanoparticles made of gold, silica and polystyrene, with diameters ranging from 30 to 400 nm, and demonstrate some of the limitations with particles of sizes 500 nm and above.

We present the use of Multi-angle Dynamic Light Scattering (MADLS®) for the measurement of nanoparticle concentration.

0 kommentar(er)

0 kommentar(er)